Availability:

Out of stock

65,432 CFA 88,045 CFA

product introduction

|

Size

|

394*120*25mm

|

|

FOQ

|

1pcs

|

|

Materal

|

copper+aluminum

|

|

Used in

|

AMD: FM1.FM2.FM2+.AM2.AM2+.AM3.AM3+AM4

Intel:LGA2011/2011-V3.1366.1150.1151.1155.1156.775 |

|

lead time

|

7-45days

|

|

heat pipe

|

liquid cooler

|

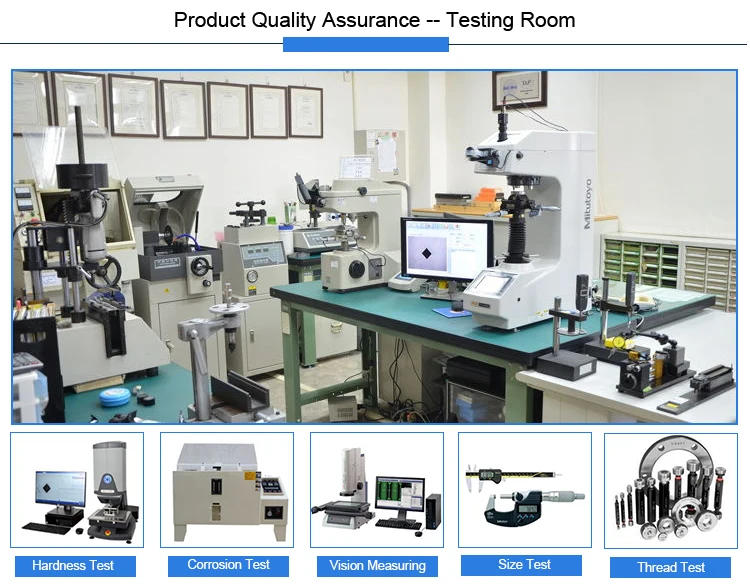

test equipment

Welding equipment

CNC Machining

Stamping

production process

Type of production

|

Product type

|

1. extruded heat sink

2. heat pipe heat sink 3. skiving fin heat sink 4. stamping heat sink 5. die casting heat sink 6. precision CNC machining heat sink 7. forging heat sink 8. heat pipe 9. cooling fan: DC computer case fan, AC fan, EC fan |

|

process

|

extrusion, skiving fin, stamping, die casting, precision CNC machining, drilling, milling, bending, soldering, etc

|

|

Surface finish

|

anodizing, electrophoresis, nickel plating, sandblasting, power plating, wire drawing, polishing, anti-oxidation coating, etc.

|

|

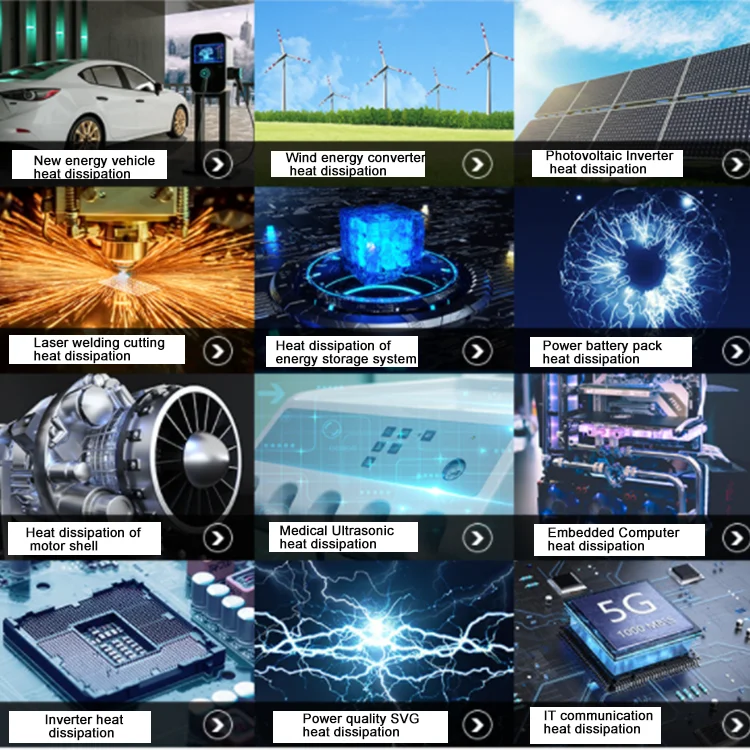

Application |

1. Computer fileds: computer mainboard, PC, IPC, Server, PCTV, Router, Power supply (CPU cooler, VGA cooler, Cooling fan)

2. Home appliances: pico projector, electronic refrigerator, red wine cooler, LASER TV, LCD TV, LED panel, Sound, Air condition, induction cooker, etc. 3. LED lighting: stage light, high bay light, down light, street light, automobile lamp ,etc. 4. Security fields: security cameras, infrared light cameras. 5. Machines: Industry/Medical/Military machines |

Our Advantages

We are the source of independent research and development and processing factories. Choose us, convenient communication, delivery time on time, avoid middlemen to earn price difference. This greatly saves time and cost.

inspection equipment

Team and office

There are no reviews yet.